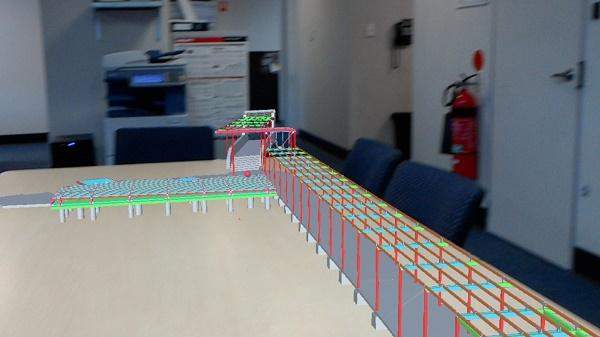

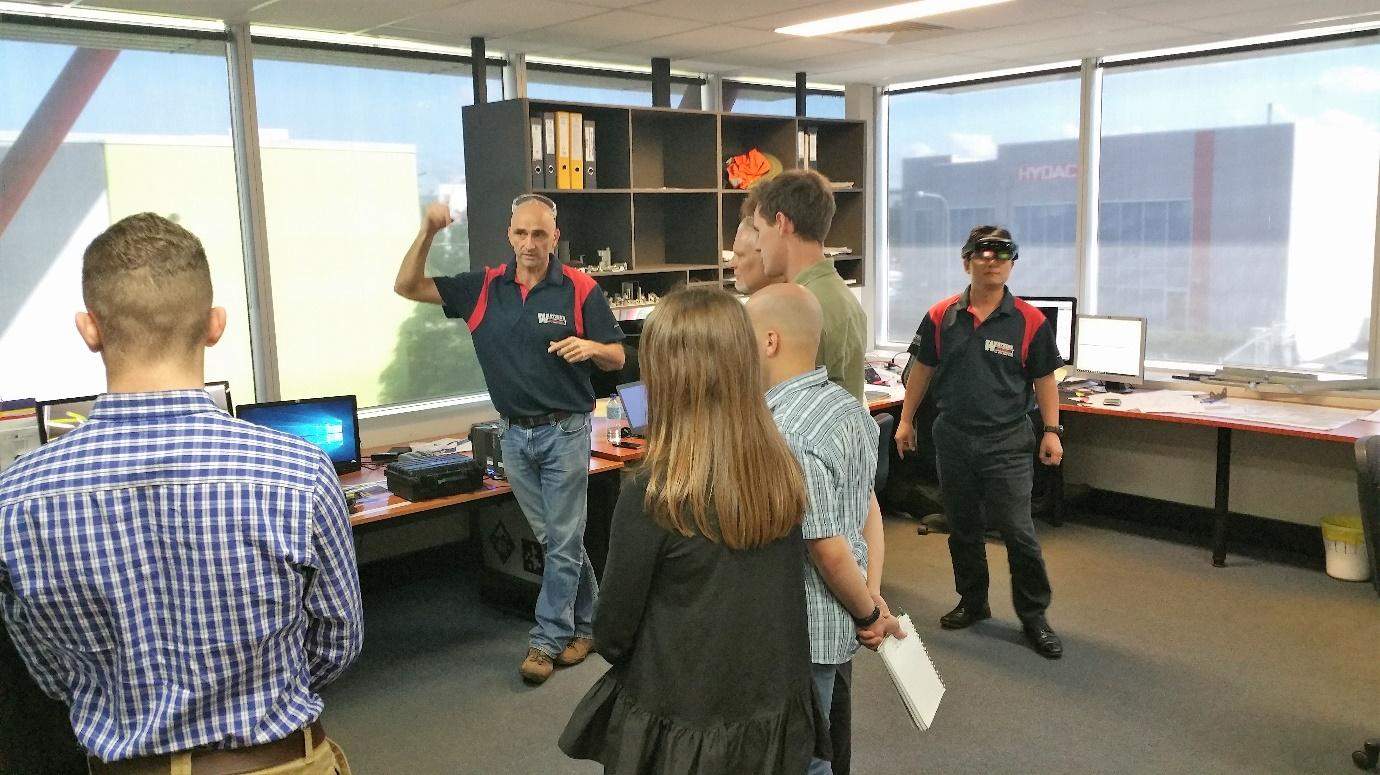

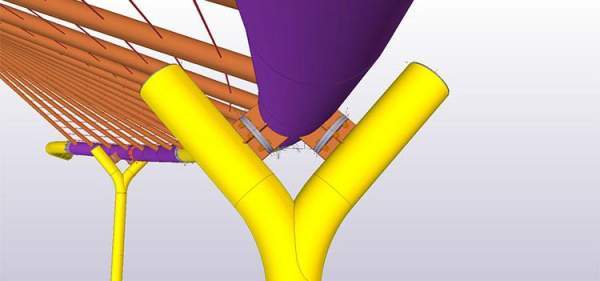

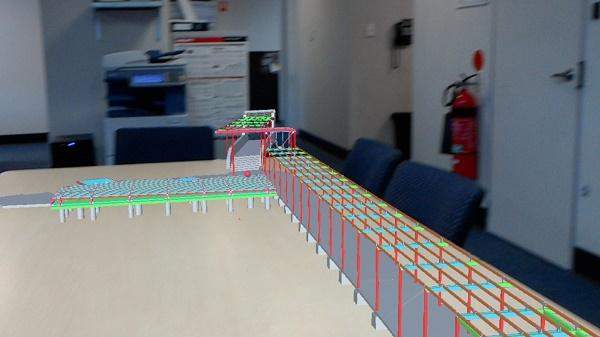

On May 22nd 2017, representatives from Be Collective and Eco Effective Solutions visited the Banyo facilities of Watkins Steel to witness a demonstration of local technological innovation. Des Watkins and Ben Yu from Watkins Steel proudly displayed their recently purchased Micro HoloLens “glasses” that allows you to view and interact with 3D models using mixed reality. The Hololens technology allows one to view and interact with 3D Tekla models off the office desktop.

Mark Thomson believes that such new technology will transform our office workplaces in the future . “in the past we were focussed on space efficiency, investigating how to minimize floor areas to maximize working environments for chair based computer workstations. Now we will ideally be creating fluid spaces where people can move about casually and safely with Hololens and other wearable devices to optimize our work experiences “ With the Microsoft HoloLens you can alter the model, scale it down, or do a life-size walkthrough – improving accuracy, communication, and collaboration at every stage of the project.

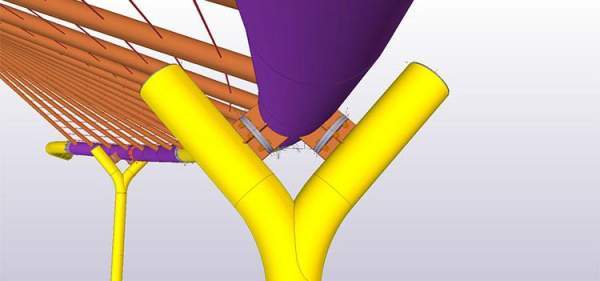

In addition to the BIM and Hololens demonstration, we were taken around the factory floor to witness the rollout of new robotized machinery being installed by an expert installation team from Holland. Watkins Steel has developed a Four step linked Process for steel fabrication and installation which includes a 3D scan of the site, Tekla 2d shop drawings and a 3D model, Voortman steel processing, and robotic total station site set outs. This end to end digitally linked process using multiple computer technologies is surely and insight into how future construction processes will rapidly develop.

After just three months the team has experimented with the HoloLens in the factory – overlaying models to steelwork to see if it can be used for Quality Assurance.